Double-strand chains for individual solutions

The best double-strand chains

Depending on the application area, double-strand chains need to be adapted to the respective requirement. We know which type is suitable for your industry and we will find the perfect solution. Standard is no good? So let's develop your long-lasting individual product together.

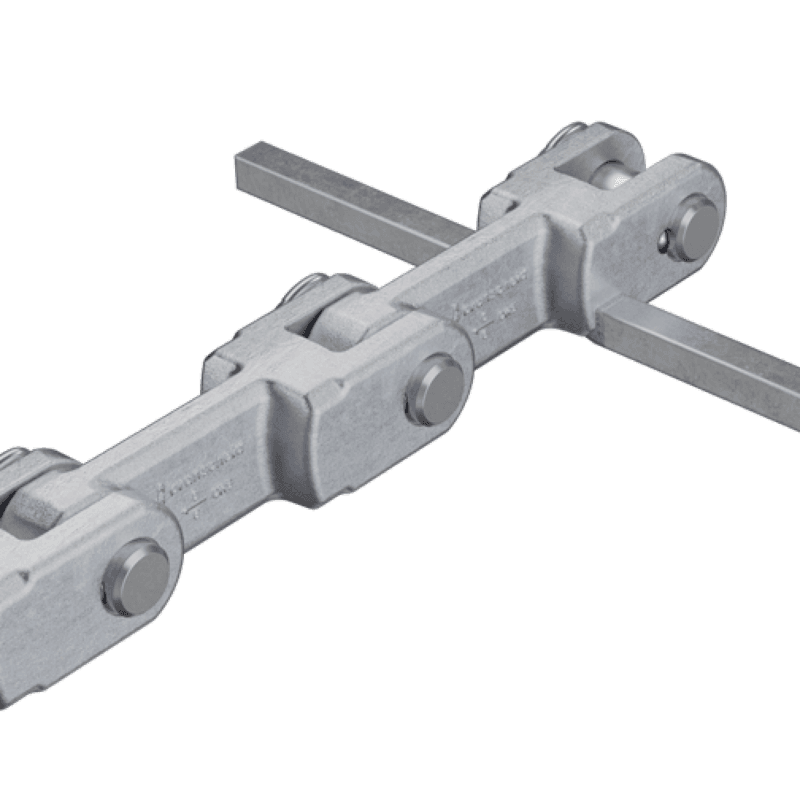

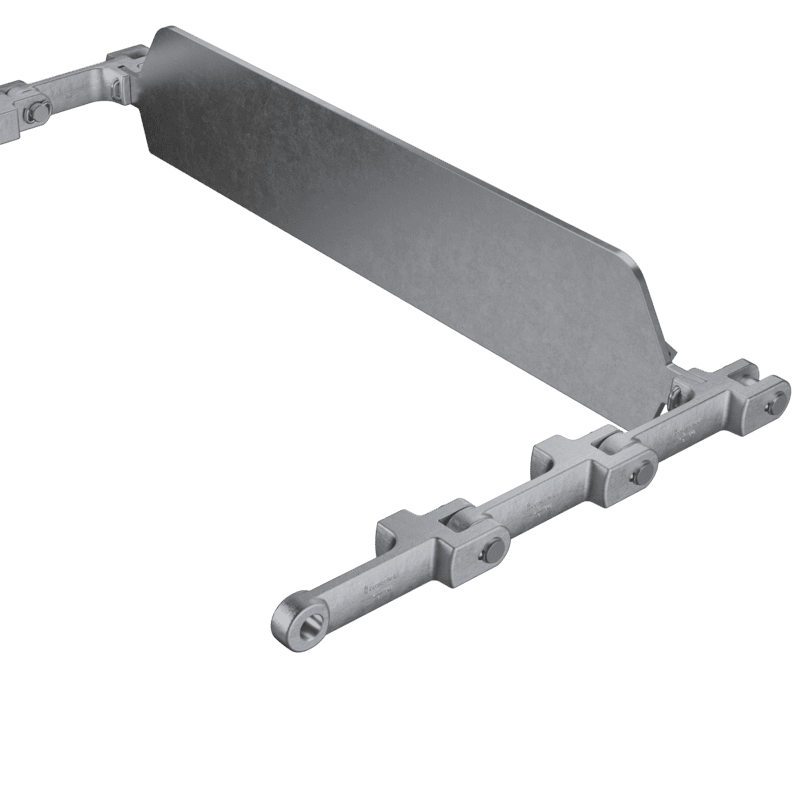

Application: horizontal, angled conveying

Conveyed material: medium to coarse-grained bulk materials such as biomass, wood chips, substitute fuels

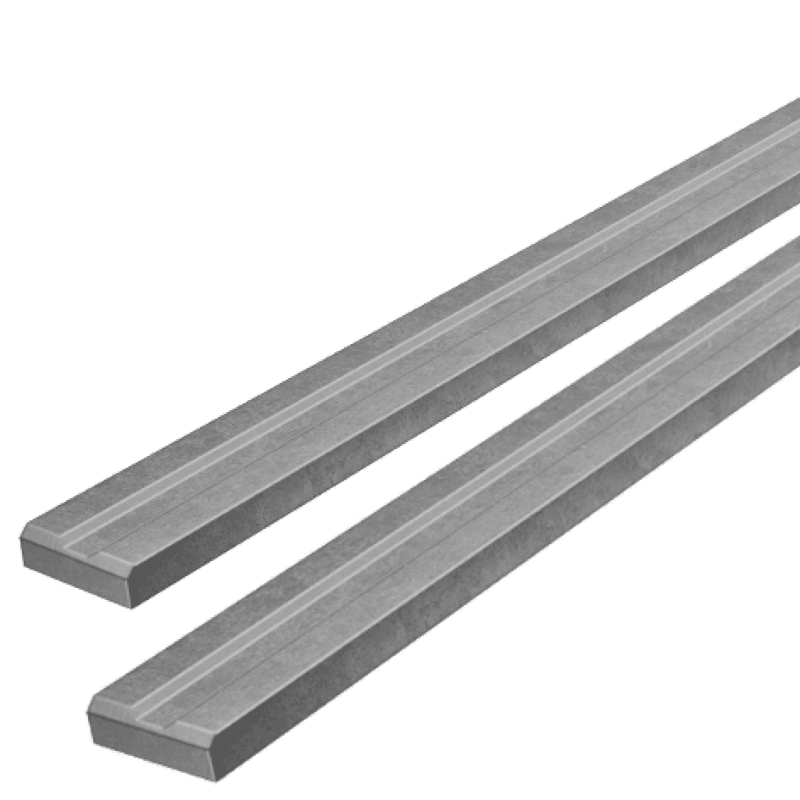

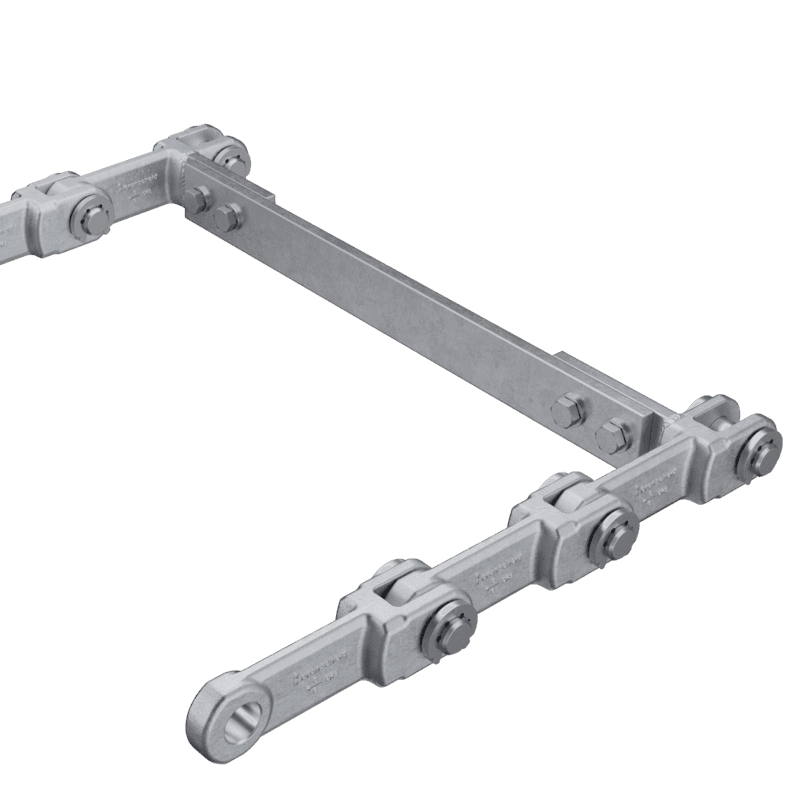

Application: horizontal, angled conveying

Conveyed material: small grain, highly-abrasive bulk materials, dusts and sand, etc.

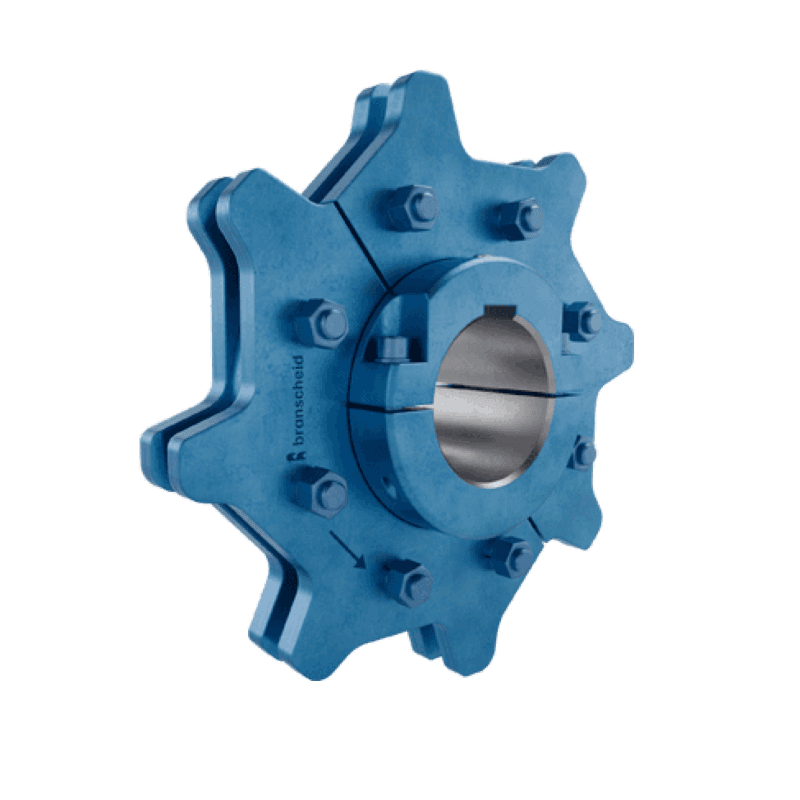

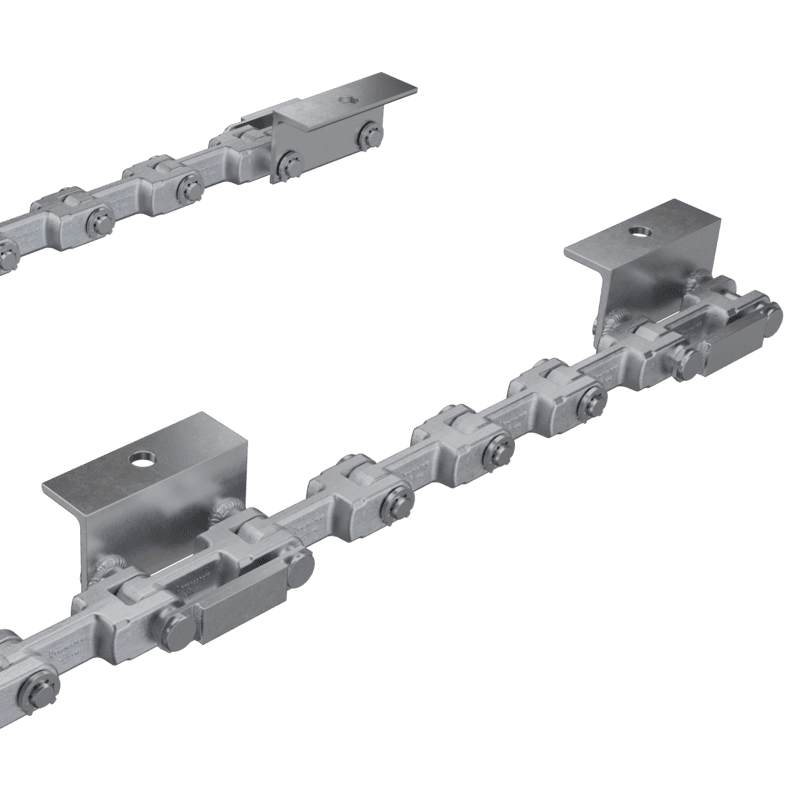

Application: horizontal conveying in bucket conveyor

Conveyed material: fine grain bulk materials such as sugar, salt, seeds, sand, etc.

Technical data & specifications

We never shy away from a challenge

Rust-resistant

Abrasion-resistant

Heat-resistant

High breaking load

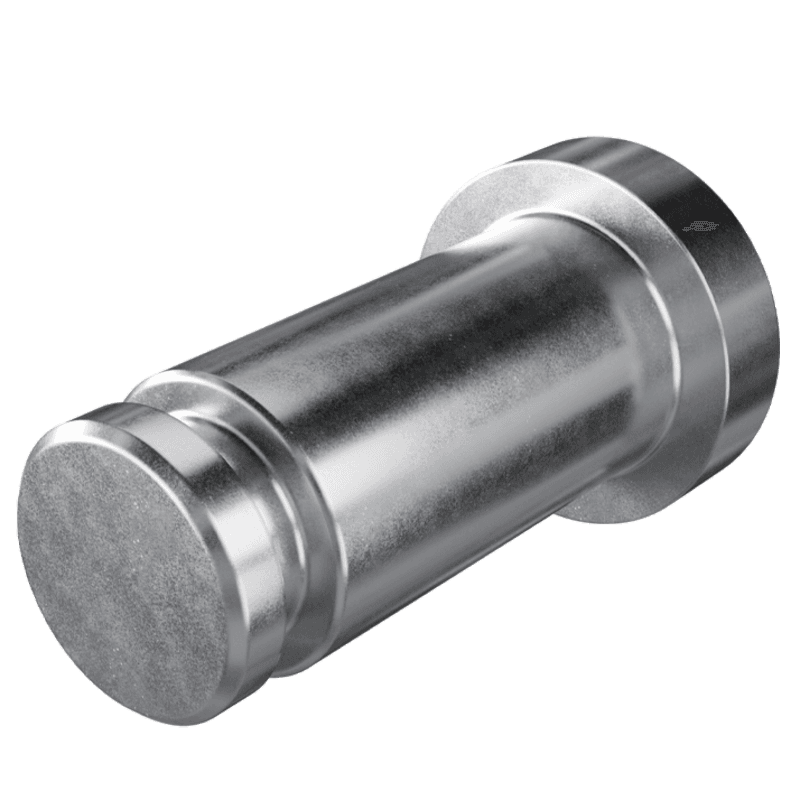

The welding process

We have a flash butt welding machine with an integrated deburring device to optimise the welded joint between the fork link and the driver. The flash butt-welding process is a computer-controlled welding process with parameter logging. Any impairment of the chain link due to uneven preheating is ruled out. The result is a homogeneous material structure and a unit between fork link and driver. We also make use of the possibilities of autogenous and inert gas welding. For use in particularly abrasive environments and for a long service life, we reinforce our chain links with high-strength armoured wire.