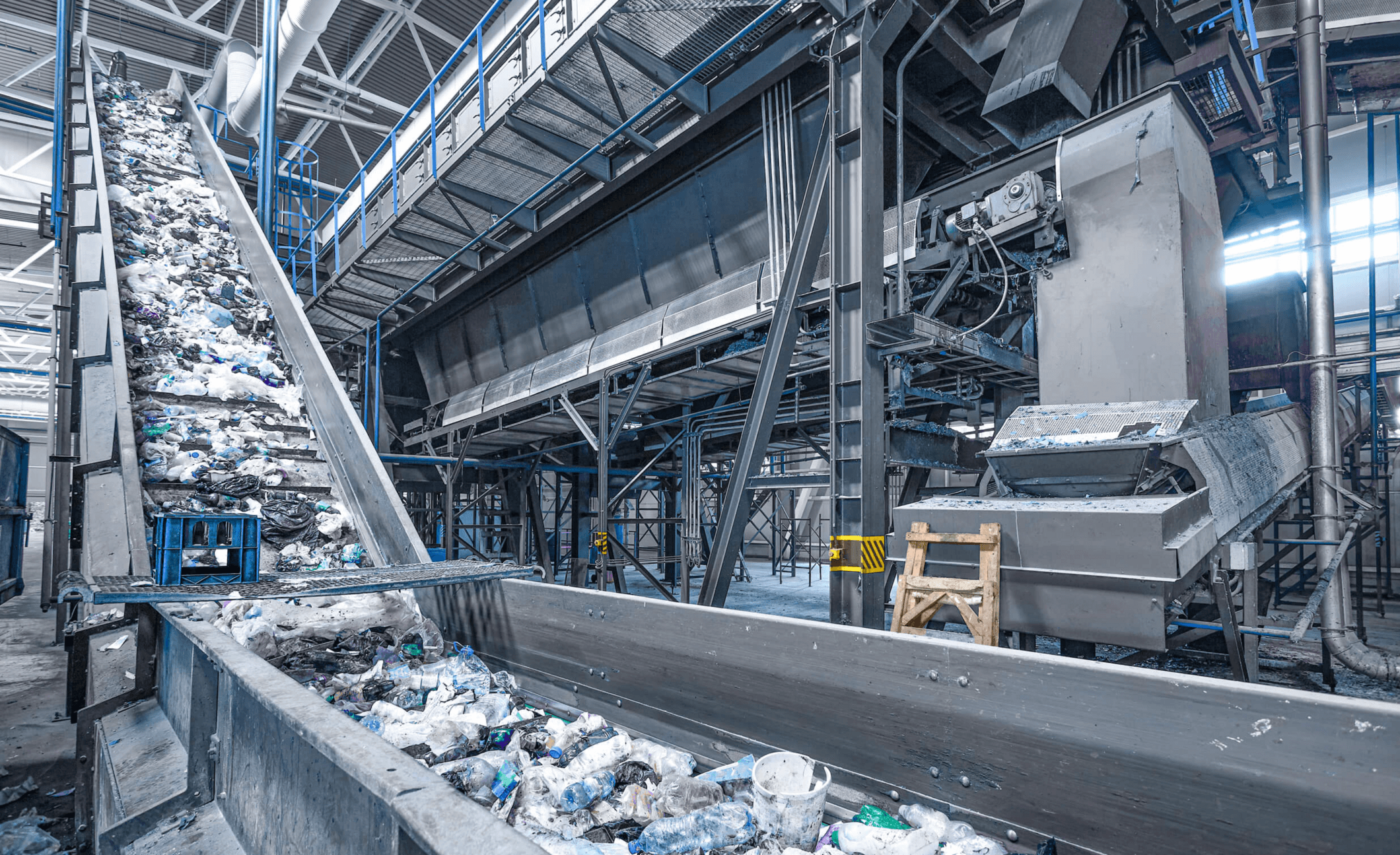

Single-strand chain for all application areas

Single-strand chains

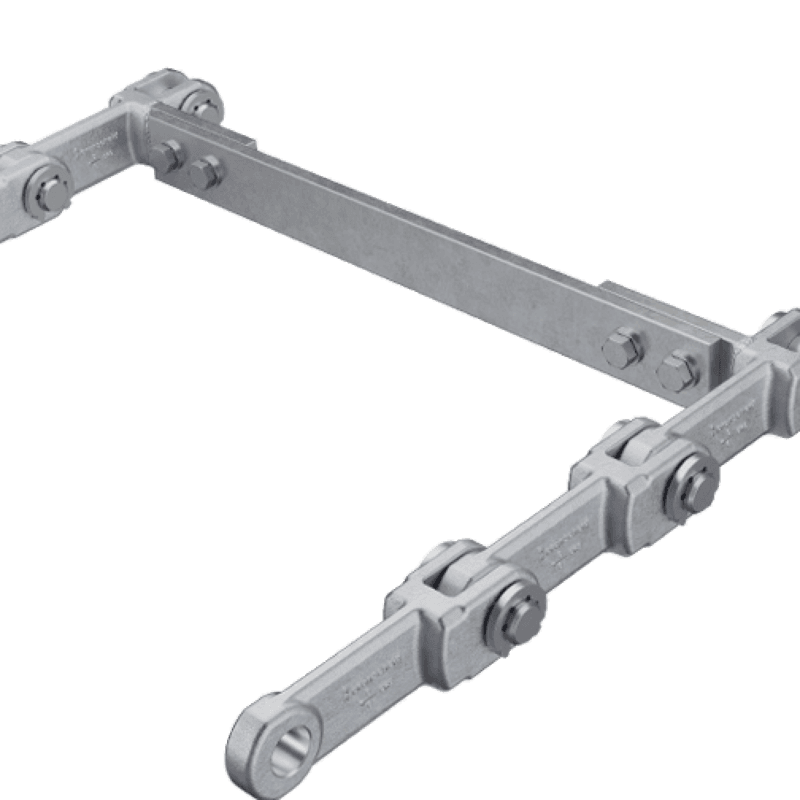

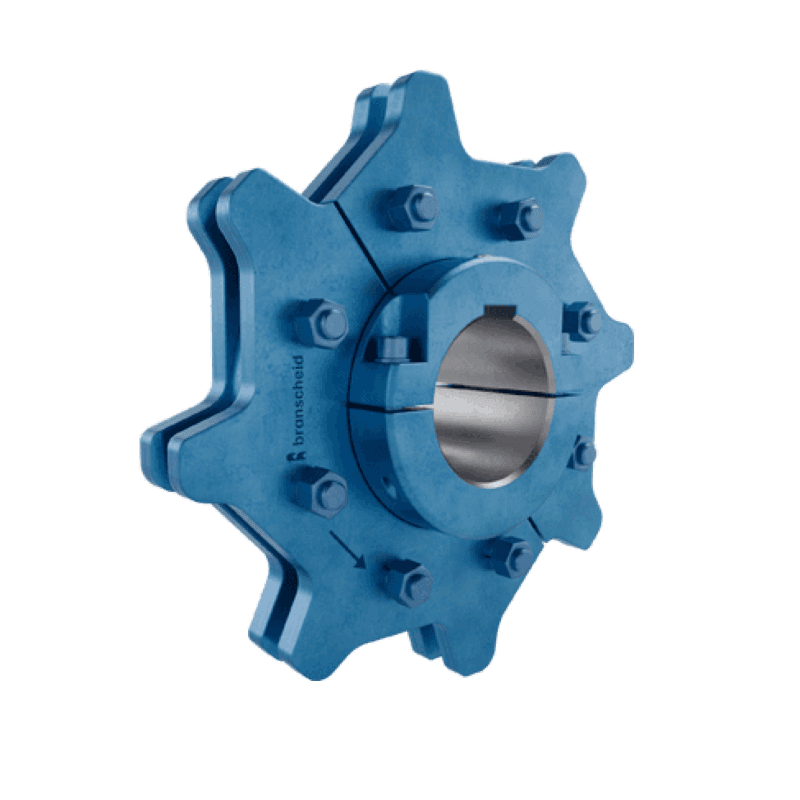

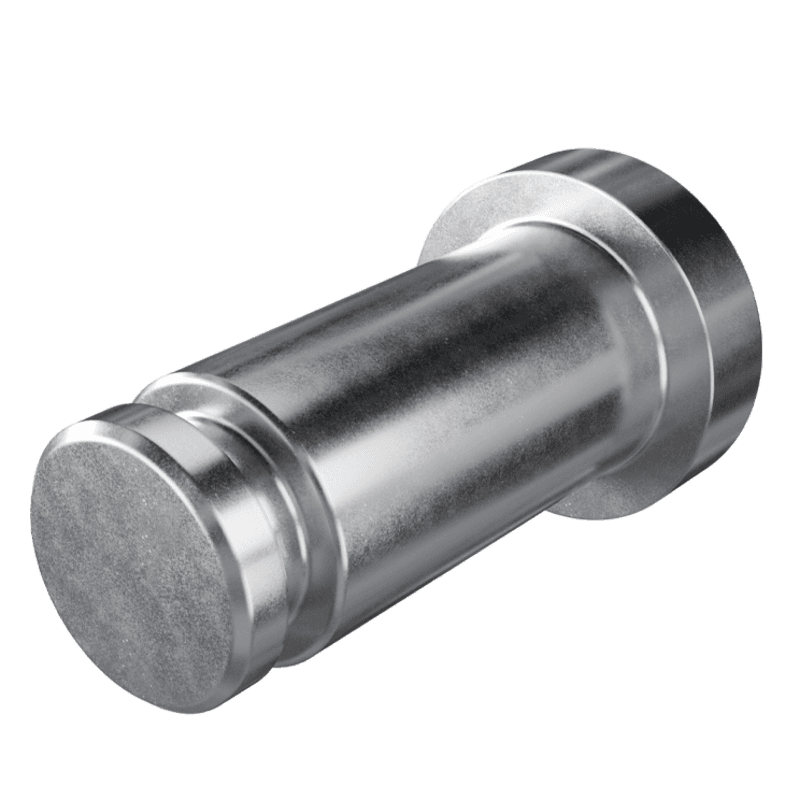

Fork link chains as single-strand chains are supplied in pitches between 102 and 315 mm and are always customised and individual solutions. The fork links we used are forged in our own production at the Branscheid Umformtechnik GmbH & Co. KG in Gevelsberg.

Alongside their short and low-cost transport routes, our fork links are characterised by particularly good material properties. The drop-forged steel and optimum utilisation of the fibre orientation give the links a very high tensile strength and make them particularly robust.

The best single-strand chains

Depending on the application area, fork link chains need to be adapted to the respective requirement. We know which type is suitable for your industry and we will find the perfect solution. Standard is no good? Then let's develop your individual product together.

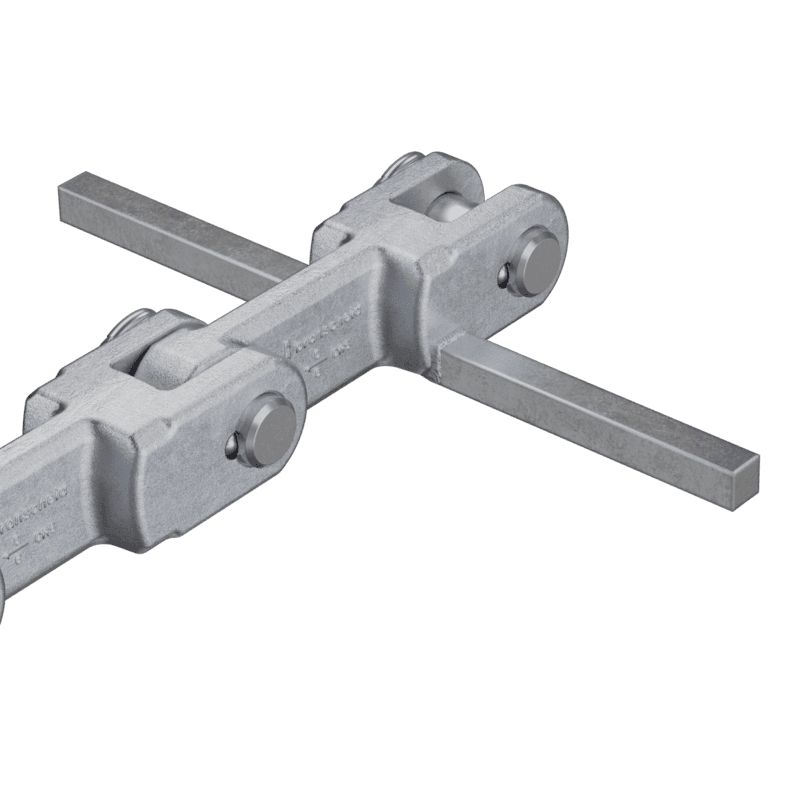

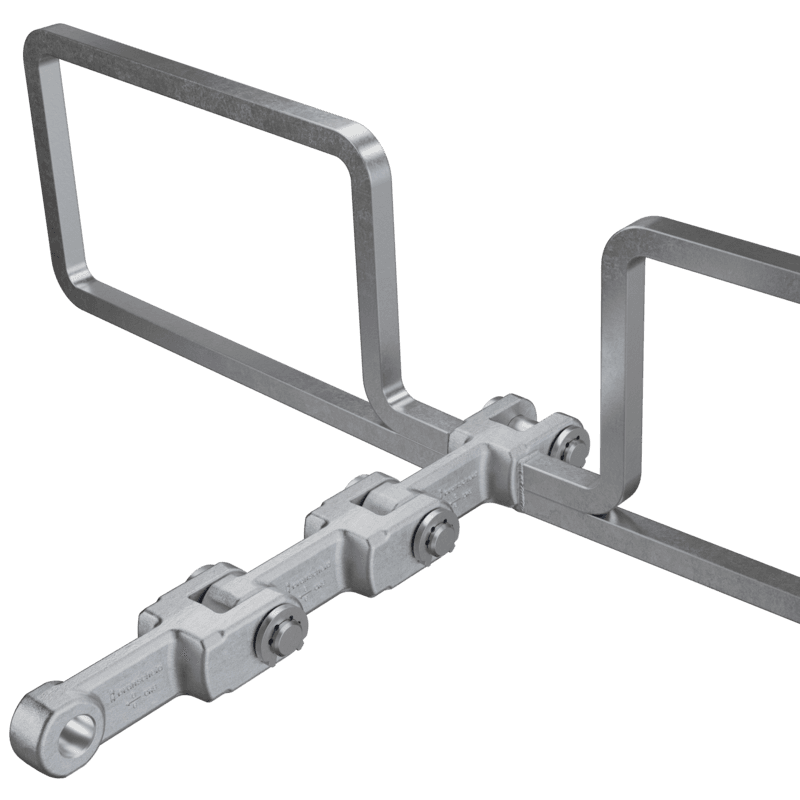

Application: horizontal to slightly angled conveying

Conveyed material: cement, clinker, chips, municipal waste, etc.

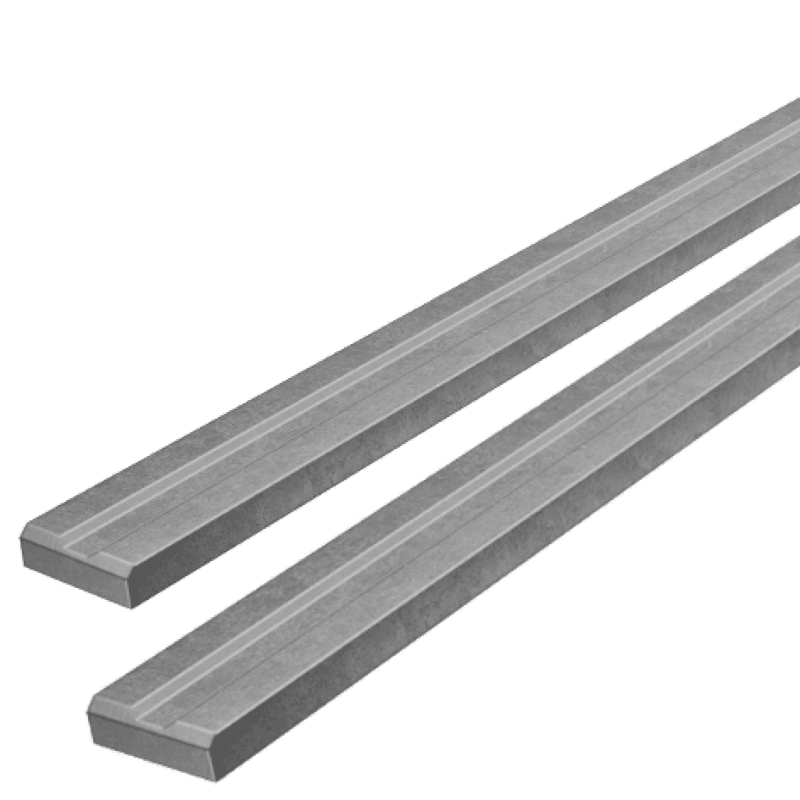

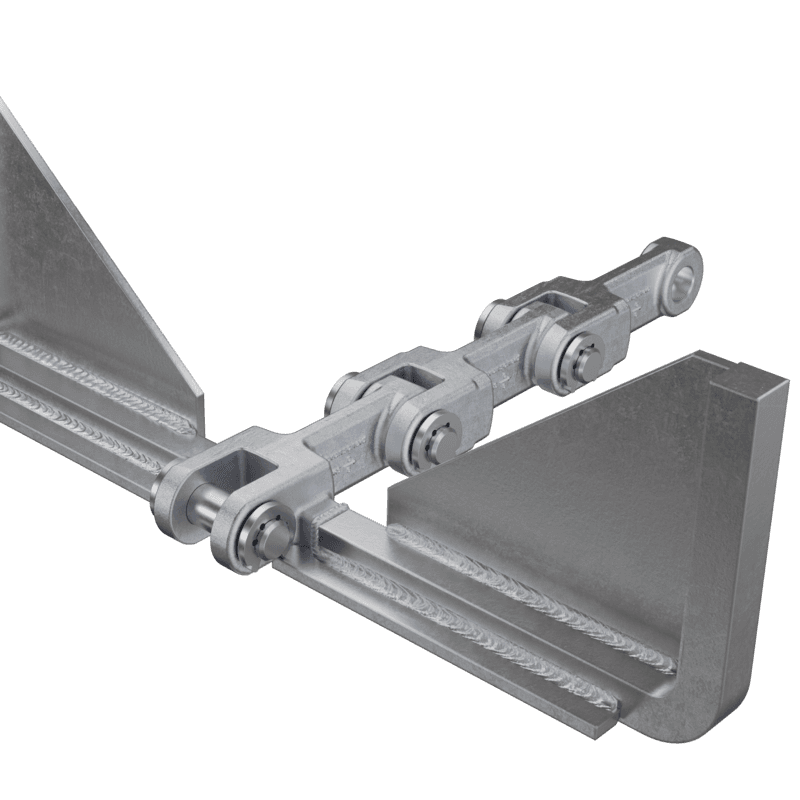

Application: scraper chain for horizontal conveying

Conveyed material: ash, powder, dusts, other small particle conveyed materials, etc.

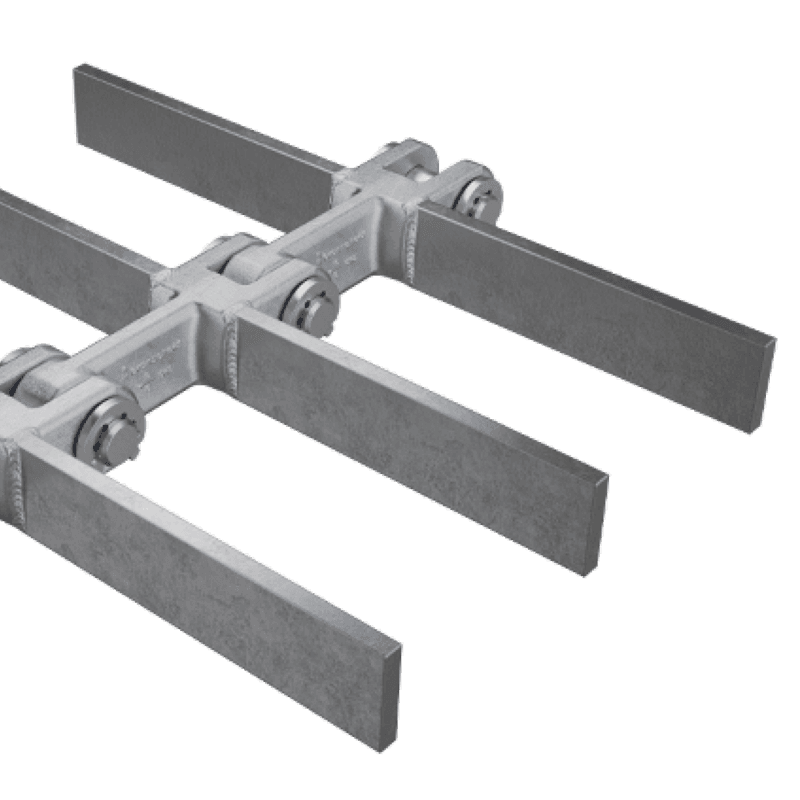

Application: horizontal, angled and vertical conveying

Conveyed material: large-volume conveyed materials, woodchips, synthetic materials, etc.

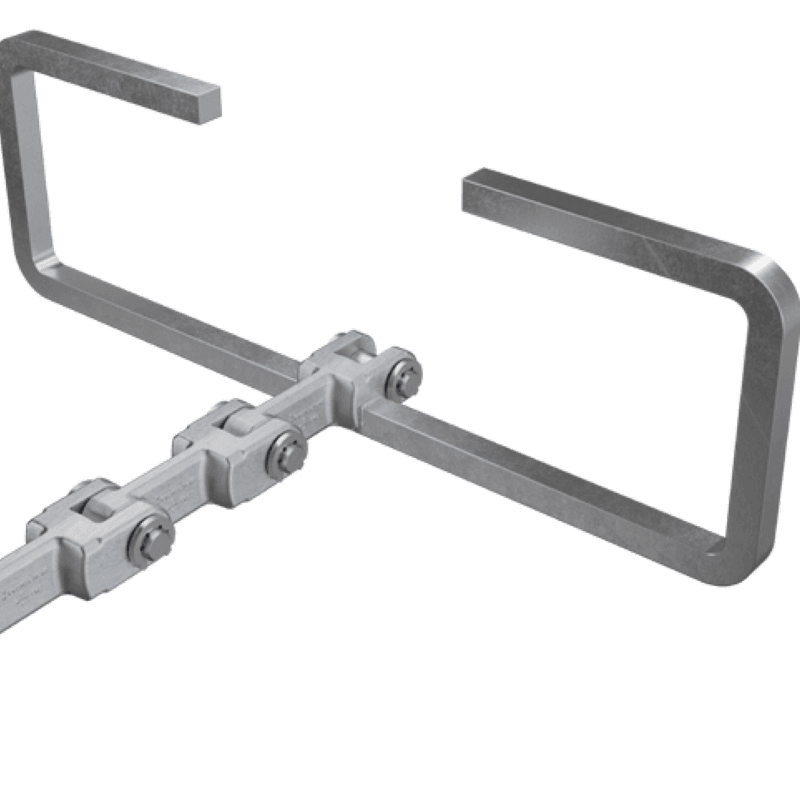

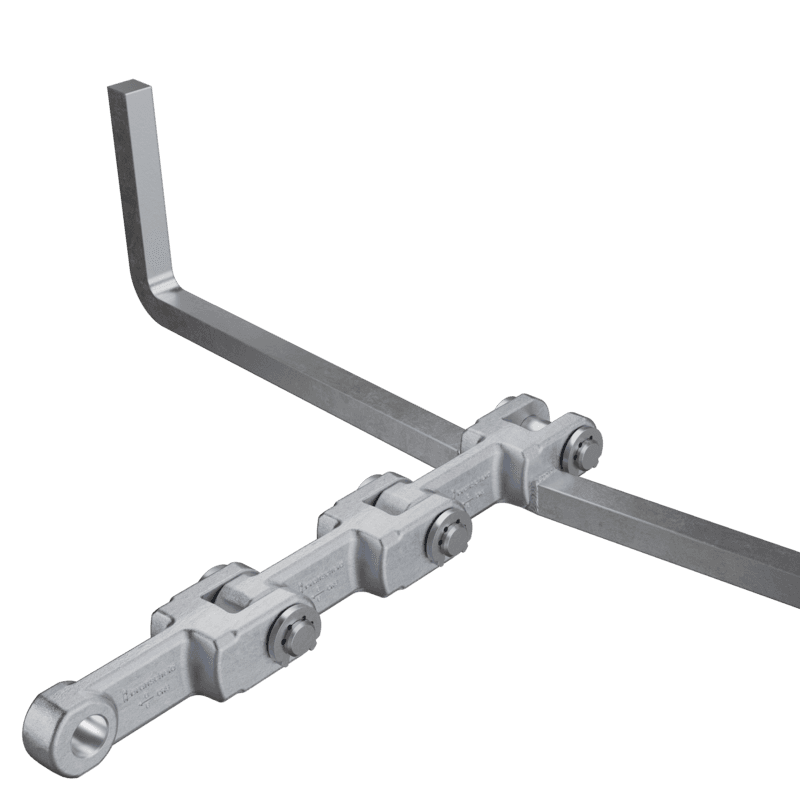

Application: horizontal, angled and vertical conveying

Conveyed material: chips, woodchips, pallets, construction materials, etc.

Application: horizontal conveying

Conveyed material: large-volume conveyors, woodchips, synthetic materials, etc.

Application: horizontal conveying

Conveyed material: large-volume conveyors, woodchips, synthetic materials, etc.

Technical data & specifications

We never shy away from a challenge

Acid-resistant

Corrosion-resistant

Highly heat-resistant

Abrasion-resistant

info@branscheid.com+49 2333 98 58 0